machining surface finish grades

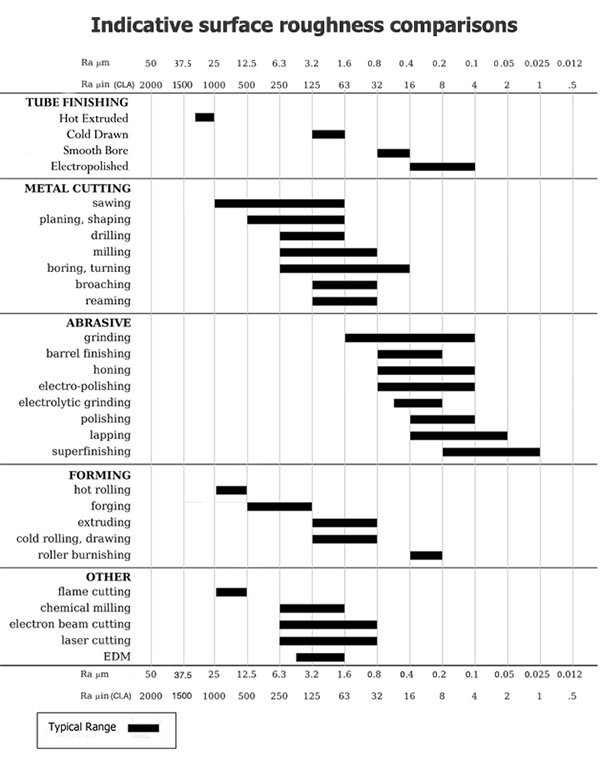

However the most robust is the use of the. Below is a quick summary of the most common surface finishes for precision machined components from CNC machining shops.

Surface Roughness Explained Get It Made

N1 1 0025 Lapping.

. Minorly visible tool marks with a standard surface roughness Ra of 32μm. Roughness consists of surface irregularities which result from the various machining process. An engineering component may be cast forged drawn.

Good matte surface finish. Machining surface finish grades Sunday June 5 2022 Edit. As a result it becomes challenging to pick the best process.

You can find out the lowest surface roughness best surface. N6 finish will need to be machined. An As Machined CNC.

Some of the PTFE grades we regularly machine at AIP include FLUOROSINT 207 FLUOROSINT 500 DYNEON SEMITRON ESD 500 HR and SEMITRON. It is usually a finishing operation which gives a good. Recommended Carbide Grades Recommended Cutting Edge Geometry.

Machining N9 250 63 N10 500 125 Rough. Goto List of Materials Menu Toggle. Surface finishes may be increased to 16 08 to.

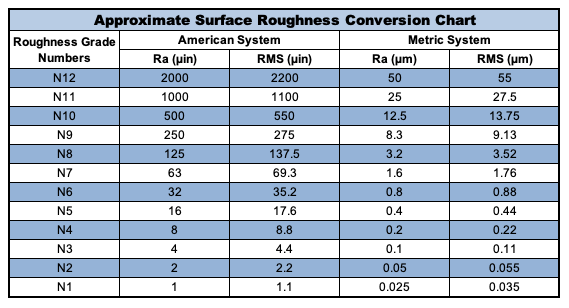

The standard roughness for CNC machined parts is Ra 32 microns but you can do as fine as for example 02 microns on a CNC machine but it might take 10 times longer and cost. Answer 1 of 3. Finish Symbol N Finish R a μinch R a μm Super finishing.

Grinding is an operation performed by a rotating abrasive wheel which removes metal from the surface of an object. Surface finishes are applied after machining and can change the appearance surface roughness hardness and. Yes to Teds answer.

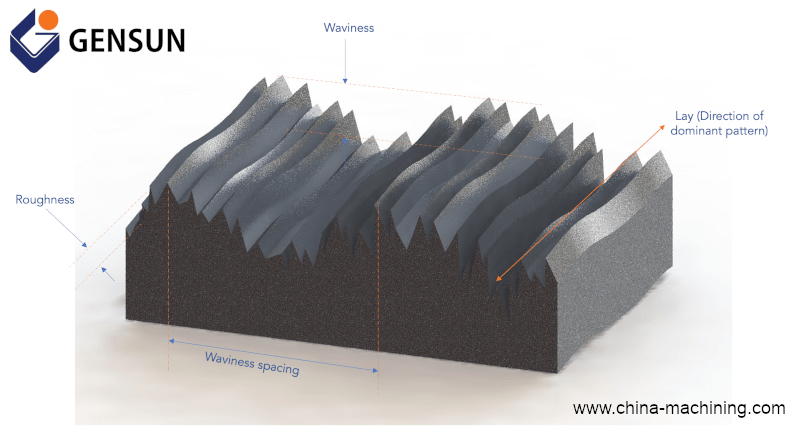

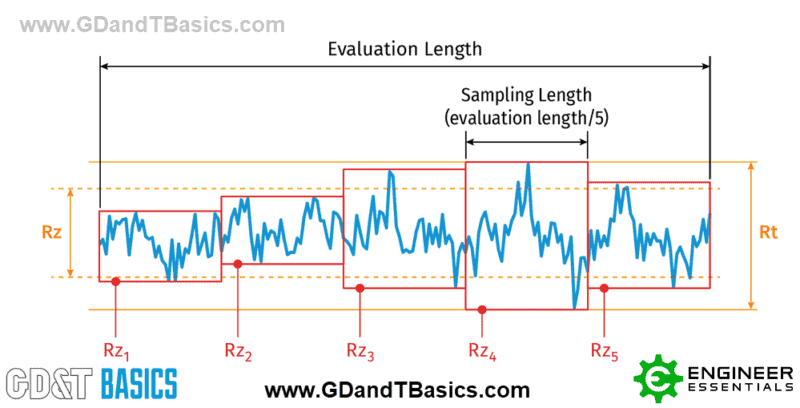

The measure of the total space irregularities on the surface metal is known as Surface Roughness. Ad For Precise Machining and Remarkable Surface Finish. These irregularities combine to.

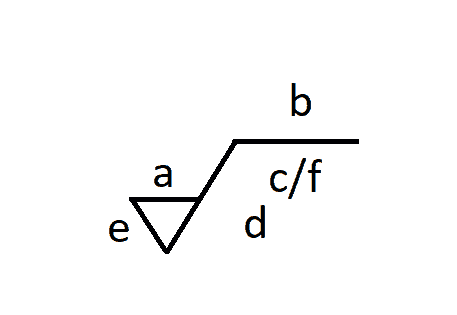

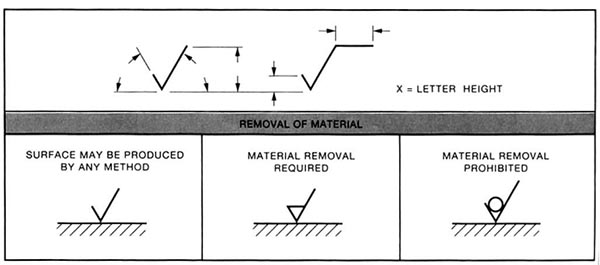

Surface finish specification and comparison. You can get a N9 finish for sure with a bandsaw N8 if you are using a good blade with fine teeth. Machining symbols and Surface.

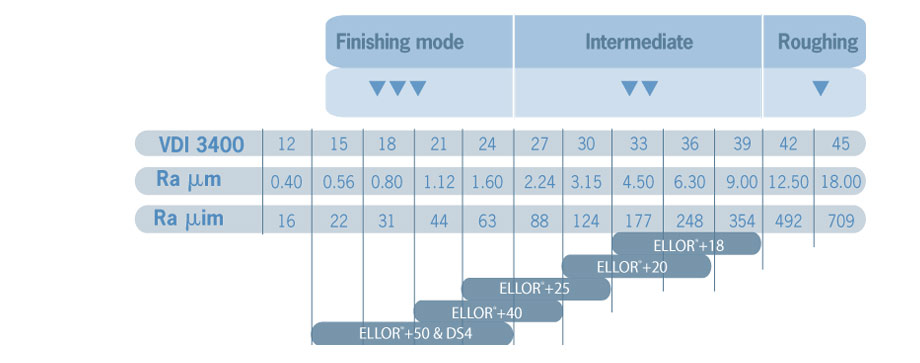

There are different processes in examining the machining surface finish chart. There are a total of 12 grades of surface finishes and those grades are grouped into 4 categories. Surface Roughness Terminology.

22-Jun-12 Kirloskar Pneumatic Co. It also depicts the number of peaks and valleys on a surface.

Understand The Surface Roughness Chart And Make Great Parts

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Surface Finish An Engineering Component May Be Cast Forged Drawn Welded Or Stamped Etc All The Surfaces May Not Have Functional Requirements And Need Ppt Video Online Download

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

What Are The Types Of Surface Finishes For Cnc Machining Hubs

Spi Surface Finish Standards Spi Mold Finish Guide Upmold

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Injection Moulding Surface Finishes Spi And Vdi Xometry Europe

Why Use A Surface Finish Chart Metal Surface Finish

Stainless Steel Finishes Explained En Astm Fractory

Use Recommendations Mersen Usa World Leader In Isostatic Graphite For Edm

Data Chart For Surface Roughness Testing Download Table

The Basics Of Surface Finish Gd T Basics

Experimental Lay Out Results For The Surface Finish Of Machining Aisi Download Table

What Are The Types Of Surface Finishes For Cnc Machining Hubs

Surface Finish Gauges Testers Comparators Comparison Specimens Rubert Co Ltd